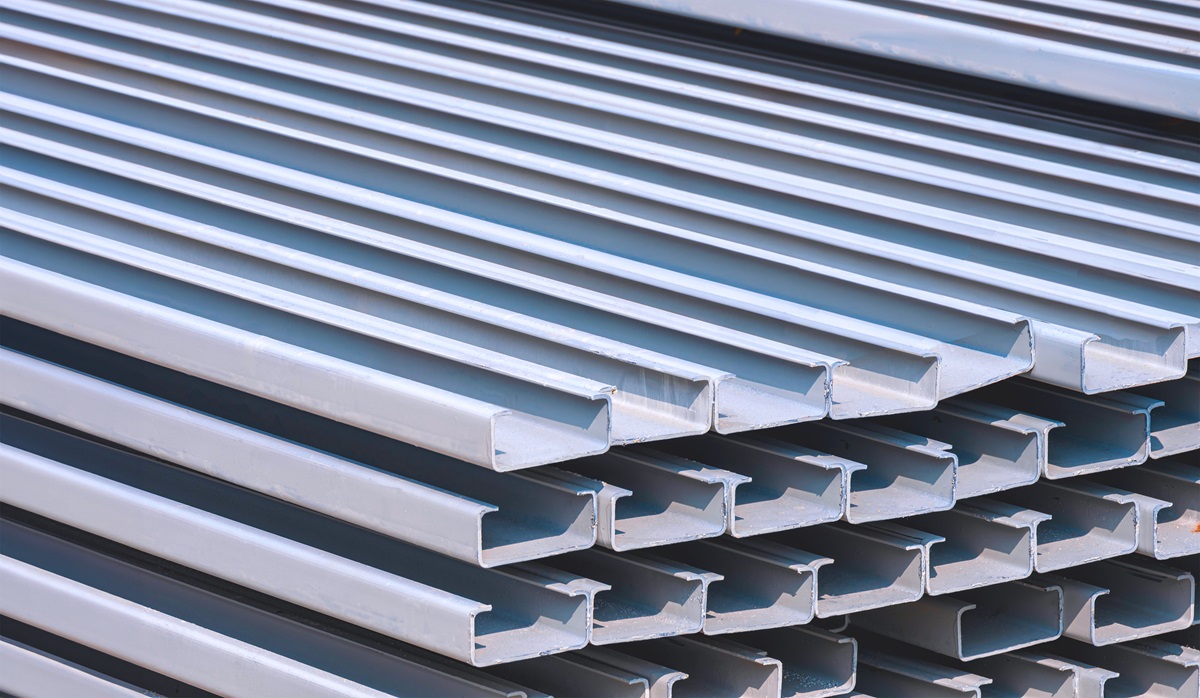

C Channel Steel Production

Our C channels are roll-formed using galvanized, hot-rolled, or cold-rolled steel, depending on your project’s structural and environmental requirements. Available in a range of sizes and gauges, these steel channels provide outstanding resistance to bending and torsion.

C channel steel is widely used in framing for buildings, trailers, metal garages, mezzanines, and purlin systems. Its high strength-to-weight ratio makes it ideal for load-bearing applications without adding unnecessary bulk or cost.

At Qomo Industries, every C channel is cut to your exact specifications, ensuring seamless integration into your framing systems. We offer both standard and custom hole punching, slotting, and notching to streamline your assembly process.

Our in-house tooling and production capabilities in Toledo, Ohio, mean faster turnaround times and greater quality control. You’ll get consistent, accurately formed steel channels that meet industry tolerances and your project timeline.

All C channel steel from Qomo Industries undergoes corrosion protection treatment, including optional powder coating or pre-painted finishes for projects requiring additional aesthetic or environmental protection.

We also offer technical support to ensure proper channel sizing, spacing, and structural integration. Whether for a large-scale industrial project or a custom metal structure, we’ll help you engineer the right solution.

For robust, custom steel channel products made in Ohio, turn to Qomo Industries—your source for structural steel solutions that last.